Cytech Systems Lab Has Successfully Introduced XRF Detection, Further Enhancing Quality Control Measure

June 07, 2023

As we all know, X-rays have been widely used in various fields, including X-ray fluorescence spectroscopy.

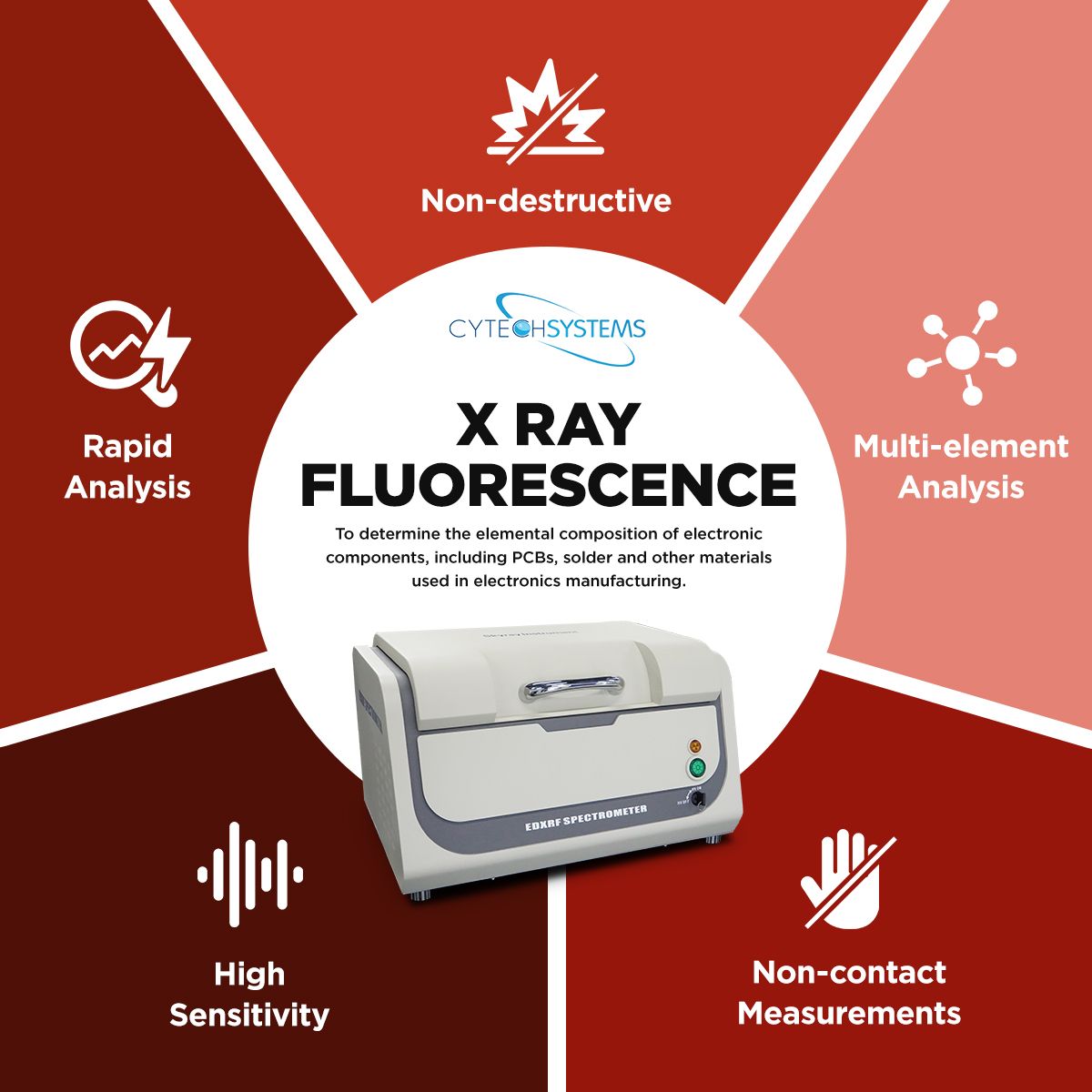

XRF, or X-ray Fluorescence, is used to analyze the elemental composition of electronic components like PCBs and solder in electronics manufacturing.

Due to its advantages such as non-destructive testing, rapid analysis, multi-element analysis, high sensitivity, and non-contact measurement, XRF has been one of the main analytical instruments in testing laboratories for decades and has been widely applied in the industry.

Principle of XRF Detection

The principle of XRF testing in electronic component inspection is similar to that in other industries. When an X-ray beam is directed at an electronic component, the X-rays interact with the electrons of the atoms in the material, causing them to be excited and move to higher energy levels. When the electrons return to their original energy levels, they emit characteristic X-rays with specific energies for each element.

By measuring the emission wavelength (λ) and energy (E) of the X-rays, specific elements can be determined, and the density of the corresponding X-ray can be measured to determine the quantity of the element. This allows for the determination of the elemental composition of the material.

Function and Application of XRF Testing

XRF testing in the electronic component inspection industry can be used not only to identify and quantify elements present in electronic waste, thus enabling the effective recovery of valuable metals but also for quality control and assurance to ensure that electronic components meet the required specifications.

Recently, Cytech Systems Lab has introduced a new XRF testing alongside existing X-ray testing, EVI testing, Decapsulation, electrical testing, and solderability testing. The lab equipment inventory has also welcomed a new partner - the X-ray fluorescence spectrometer, providing new momentum for the company's quality control.

In terms of quality control and assurance in the electronic component industry, the X-ray fluorescence spectrometer includes the following functions:

-

Elemental analysis: Analyzing elements ranging from sulfur (S) to uranium (U), it can be used to determine the composition of the ceramic body in ceramic capacitors, enabling a rapid differentiation between Class 1 and Class 2 capacitors.

-

Hazardous substance screening: The most widely used function, it can analyze whether chemical elements such as lead, chromium, cadmium, mercury, and bromine specified by RoHS regulations are present in the terminals of chips and the composition of mold package materials. It can also detect whether product terminals contain lead.

However, it should be noted that:

-

XRF can not distinguish compounds or the valence state of elements. For example, if XRF analysis detects a bromine content or chromium content exceeding 1000 ppm in a sample, other methods should be used to determine whether it contains polybrominated biphenyls, polybrominated diphenyl ethers, or hexavalent chromium.

-

A negative result from XRF screening for lead, chromium, cadmium, mercury, and bromine does not guarantee compliance with RoHS 2.0 since the four additional phthalate substances introduced in RoHS 2.0 cannot be detected by XRF screening.

Significance of Introducing XRF Testing

As a leading distributor of electronic components, Cytech Systems is well aware of the importance of component quality and considers it as the cornerstone of the company's growth. The successful introduction of XRF testing in the lab is a significant milestone, as it not only enhances the testing capabilities and overall quality control but also ensures speedy delivery by guaranteeing component excellence.